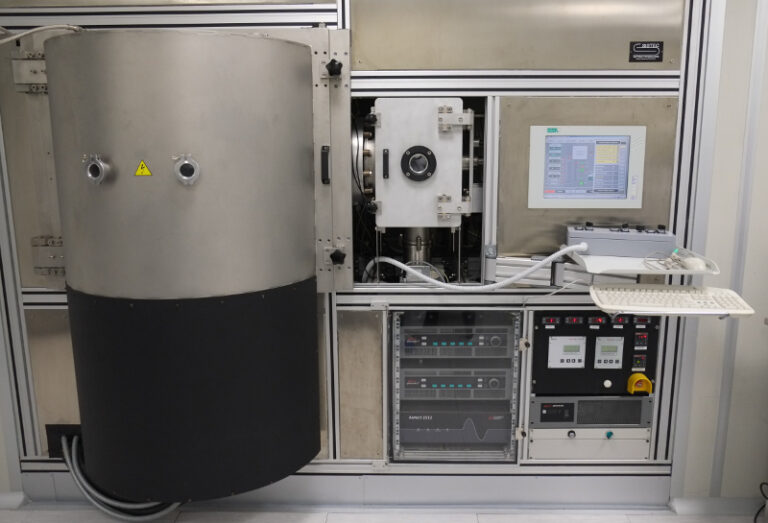

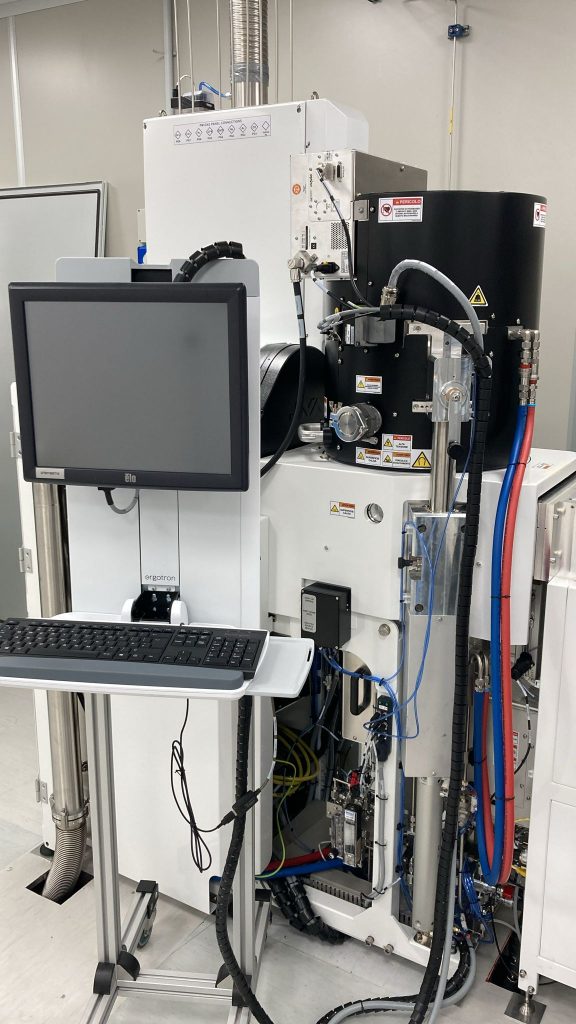

RIE – SPTS Omega SYNAPSE 200 LPX

Details

Description:

The SPTS Omega SYNAPSE plasma etcher is a multipurpose Reactive Ion Etch (RIE) instrument designed for dielectric materials etching.

This tool allows anisotropic etching of silicon dioxide and nitride, as well as other materials compatible with fluoride/fluorocarbon chemistry.

The tool comes with a manual, single wafer loadlock for ease of use in a research environment. It can host 200mm wafers down to small chips.

Working principle

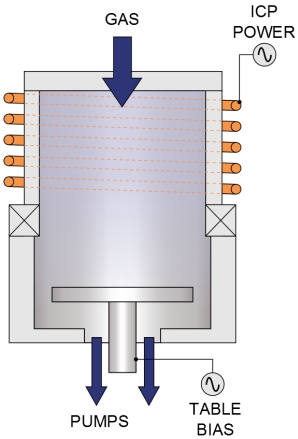

RIE uses chemically reactive plasma to remove material deposited on wafers. The plasma is generated under low pressure (vacuum) by an electromagnetic field. High-energy ions from the plasma attack the wafer surface and react with it. In ICP type of system, the plasma is generated with an RF powered magnetic field. Very high plasma densities can be achieved, though etch profiles tend to be more isotropic.

- High etch rates are achieved by high ion density (>1011 cm3) and high radical density

- Control over selectivity and damage is achieved by low ion energy

- Separate RF and ICP generators provide separate control over ion energy and ion density, enabling high process flexibility

- Low pressure processing yet still high density for improved profile control Chemical and ion-induced etching

- Can also be run in RIE mode for certain low etch rate applications

- High conductance pumping port provides high gas throughput for fastest etch rates

- Fast action mass flow controllers allow fast gas switching during processes

- Electrostatic wafer clamping and helium cooling as standard, providing excellent temperature control with the option of a wide temperature range

Schematic of an ICP RIE reaction chamber

Specifications

- Inductively coupled plasma (ICP) power source

- Radio frequency (RF) power source

- Electrode temperature range: -10 °C to 20 °C.

- Available process gases: hydrogen (H2), helium (He), argon (Ar), octafluorocyclobutane (C4F8), trifluormethane (CHF3), and sulfur hexafluoride (SF6), oxygen (O2)

- Anisotropic etching of silicon and silicon oxide.

Supported Sample Sizes:

- Maximum wafer diameter: 200 mm (8 in).

- Small pieces supported: Yes, provided they can be glued to 8″ silicon carrier

- Smaller wafer sizes: to be discussed with tool manager

Typical Applications:

- Silicon and silicon oxide/nitride stack etching.

- Optical device fabrication.

- General device patterning.