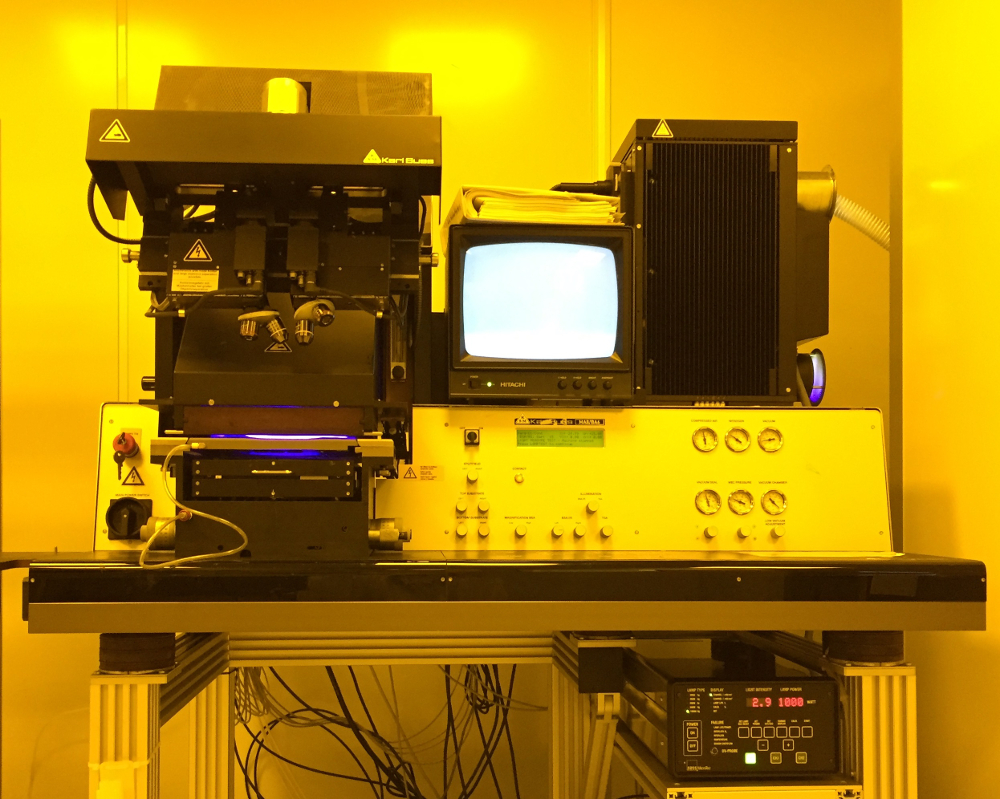

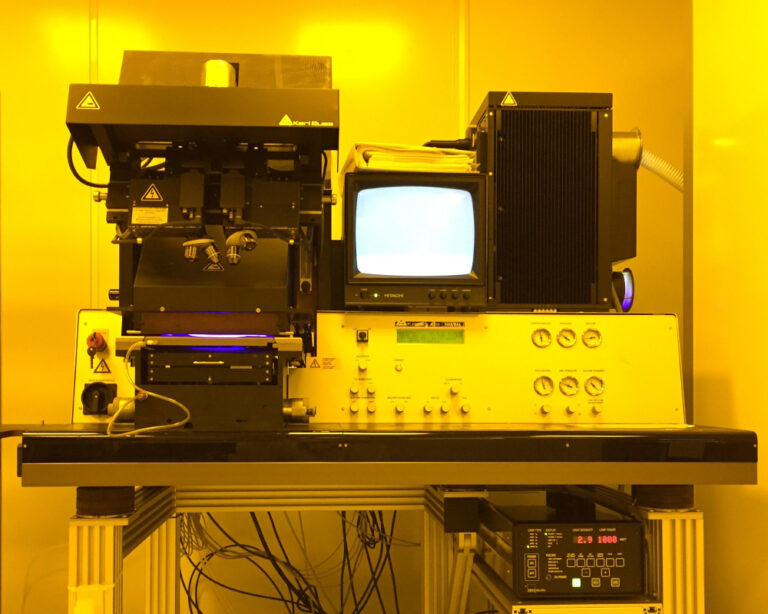

Mask Aligner – Karl Süss MA6/BA8

Details

Description

The Karl Suss MA6 is a top and bottom side contact printer used for fine lithography down to 1 micron or better. The MA6 is ideal for use with I-line (365 nm) resists and is capable of processing up to 6-inch wafers. It is equipped with a 1000 W mercury arc lamp with smart power supply capable of operating in constant power mode, or constant intensity mode. Top side wafer alignment is performed using a conventional microscope, wafer and mask stage assemblies. Bottom side alignment is done by using bottom viewing optics, CCD imaging with image frame grabber and TV monitor. This allows registration of features on the backside of a wafer to the topside of the same wafer (e.g. through wafer etching, backside window etching for membrane formation, back side masks for wafer-wafer bond alignment, etc.). The system features an automatic computer control with LCD status for User prompting and keypad entry, up to 100 programs may be stored with five on line at any one time and each program may be edited for key parameters pertinent to the lithography mode. Five lithography modes may be used for exposure: soft contact, hard contact, vacuum contact, low vacuum contact, and proximity. Each mode is easily selected by keypad and may have certain parameters changed by the user. Mask sizes from 5-inch to 7-inch may be used by selecting the suitable mask holder. Different size chucks are available for patterning of either 4- or 6-inch diameter substrates and smaller pieces may be mounted as well.

Specifications

- Wafer size: up to 6 inches

- Mask size: 5-inch to 7-inch

- Lamp: 1000 W mercury arc lamp (365 nm and 405 nm)

- Alignment type: top side and bottom side

- Lithography modes: soft contact, hard contact, vacuum contact, low vacuum contact, and proximity

- Ultimate resolution: 0.8 mm