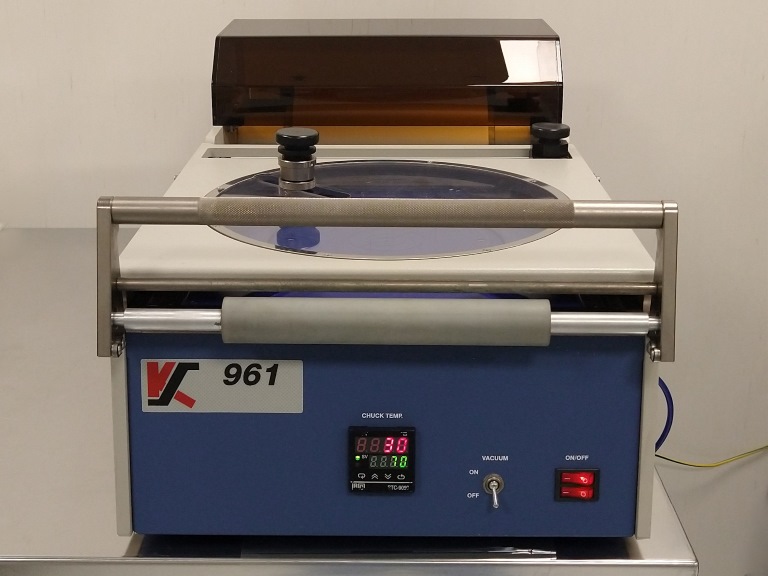

Lapping & Polishing System – Logitech PM6

Details

Manufacturer

Logitech Ltd

Website

Contact person

Stefano Bigoni, Gianluca Cannetti

Location

Description

The Logitech PM6 is a precision lappping and polishing system for bulk material removal or surface finishing of flat substrates up to 4″ in diameter. Materials include Silicon, compound semiconducors, glass

Precise plate set-up options combined with an intuitive control system provide an effortless consistency of results with a very high degree of accuracy.

Optical-grade surface roughness (sub-5 nm) can be obtained with the polishing process.

Features

- Driven jig roller arms for increased accuracy and repeatability.

- Recipe mode feature, allows operators to create, save and re-call multi-stage process recipes.

- Metered abrasive feed unit with the peristaltic pumps

- Graphical User Interface (GUI) including: plate speeds, material removal rates, driven jig arm, abrasive feed – giving the operator complete control.

- Automatic drip detector, stopping the plate rotating when the abrasive cylinders are empty

- Real time data collection and feedback via Bluetooth to allow users to export information via the USB port for external analysis.

- Bluetooth automatic-plate-flatness control provides continuous in-situ measurement of the plate flatness.

Specifications

- Plate speed: 5 to 100 rpm

- Maximum sample size: 4″/100 mm diameter

- Abrasive flow rate: 1 to 100 ml/min

Do you have any question on this equipment?