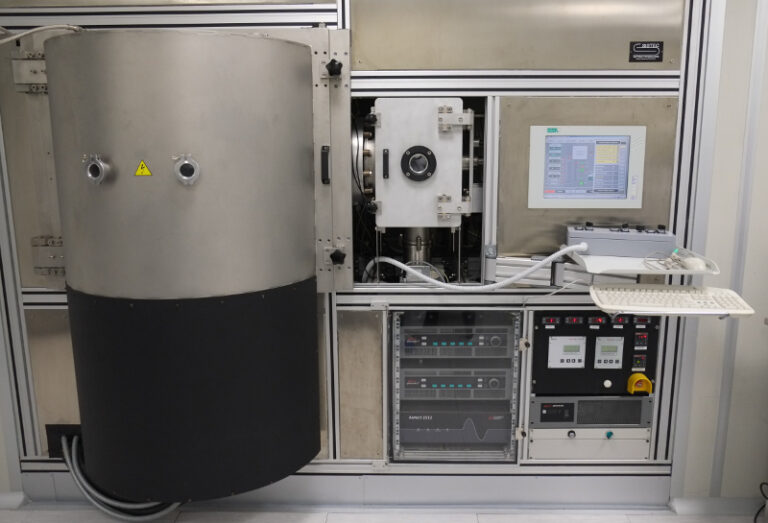

HF Vapor Phase Etcher – Idonus VPE 100

Details

Description

The Vapor Phase Etcher allows to perform quasi-dry etching of substrates using Hydrofluoric Acid (HF) in its vapor phase.

Its typical application is the release of MEMS by thermally-controlled etching of the SiO2 layer on SOI substrates.

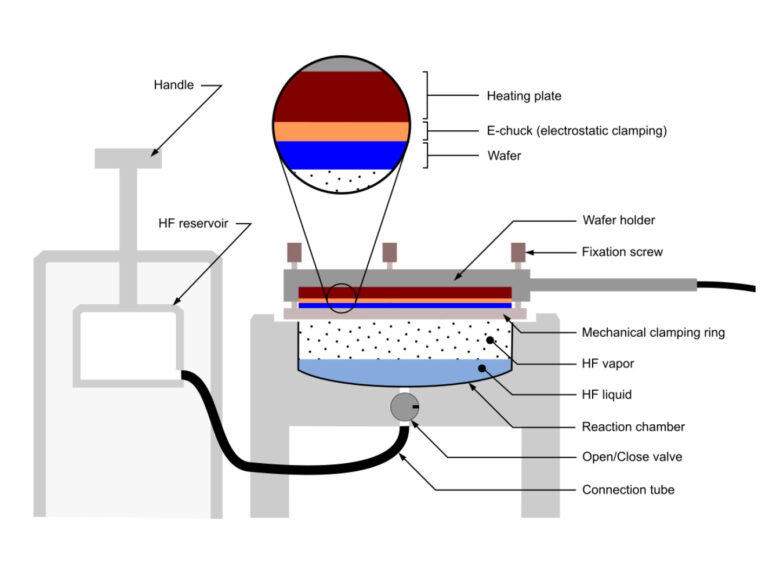

Working principle

Since liquid HF would destroy tiny structures or make them stick together due to its cohesion forces, etching is performed with only vapor in contact with the substrate.

To achieve that, the reaction chamber is filled with liquid HF and the substrate is clamped on the lid (see figure below).

HF evaporates at room temperature and the etching process starts spontaneously, but the etching rate can be adjusted in a reproducible way by controlled heating of the substrate, which affects the amount of vapor on the substrate.

HF can be re-used for multiple etchings, by transfering the acid to the HF reservoir during substrate exchange and later refilling the reaction chamber.

The simplified chemical reaction of the etching process is

SiO2 + 4 HF → SiF4 + 2 H2O ,

where fluoride (F–) ions are consumed and form SiF4 (gas) and H2O by intermediate formation of silanol groups: water vapor thus comes into play in the etching rate of silicon dioxide.

Specifications

- Typical etch rates: 4 – 10 μm/hour

- Operating temperature: 35 °C to 60 °C

- Maximum wafer diameter: 100 mm (4 in).

- Small pieces supported: Yes.

- Etchant volume : 100 mL (max 160 mL)